Formula Review

- To calculate total item time:

Total item time = setup time + (quantity × run time per unit)

- To calculate available capacity:

Available capacity = number of machines available

× number of shifts used

× number of hours per shift

× utilization × efficiency

Solved Problems (See student companion site for Excel template.)

•Problem 1

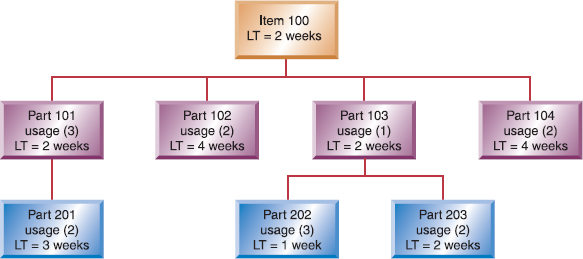

Using the product tree shown in Figure 14-6, calculate the cumulative lead time for Item 100 if you have no inventory.

FIGURE 14-6 Product structure tree

•Before You Begin:

Determine the minimum amount of time needed to build Item 100. To find the cumulative lead time, calculate the total time it takes for each connected pathway from the lowest level up to the finished product. If there is no inventory in stock, this represents the quickest way you can respond to an order for this item. Then, consider the effect of having some inventory on hand. Inventory of component parts and/or subassemblies can reduce the amount of time it takes to respond to an order.

•Solution

Check all the paths through the product structure tree to find the longest path.

| Path through the Product Structure | Total Lead Time (weeks) |

| Part 201 to Part 101 to Item 100 | 7 |

| Part 102 to Item 100 | 6 |

| Part 202 to Part 103 to Item 100 | 5 |

| Part 203 to Part 103 to Item 100 | 6 |

| Part 104 to Item 100 | 6 |

How long is the lead time if you have enough inventory for Parts 102, ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.