6.9 Six-Layer Boards

Six-layer boards can be constructed by adding outer layers of copper foil to a four-layer layup. The layers of prepreg that bond the foil layers control the dielectric thickness. Another construction is to build the core from two clad laminates separated by prepreg and then add the outer layers of foil to form the layup.

A six-layer board allows for layups with adjacent ground and power planes. This geometry provides a distributed decoupling capacitor for the board. The closer the energy sources are to the loads the faster the energy can be supplied when there is a demand. The vias that connect this energy to the load must be closely spaced. This topic was covered in detail in Section 2.14.

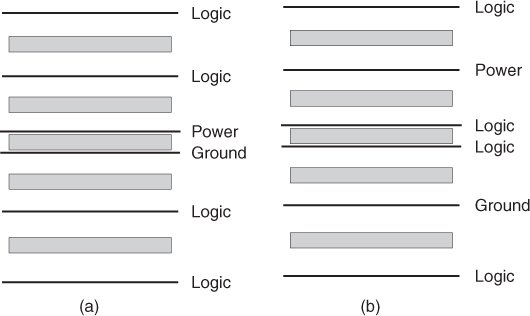

Trace layers must be near conducting planes for effective control of the characteristic impedance. It is preferred to have a ground or a power plane on each side of a trace layer. Examples of six-layer layups that can be a problem are shown in Figure 6.18.

Figure 6.18 Layup designs for six-layer boards that should be avoided.

In these layups, the ground/power planes are spaced, so they do not supply much energy to the logic. In Figure 6.18a, the outer logic layers are not near a ground or power planes so that cross talk is likely.

In logic designs where the rise and fall times are short, the problem of cross talk is present. In general, cross talk is reduced for traces ...

Get Digital Circuit Boards: Mach 1 GHz now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.