8.2 OPTIMIZING THE VVT STRATEGY

The purpose of this section is to demonstrate the various optimization techniques explained earlier. This is accomplished using quality and system data obtained from the industrial pilot project development conducted under the SysTest project at the Lahav Division of the Israel Aerospace Industries (IAI) during the timeframe 2003–2005.

8.2.1 Analytical Optimization of Cost

Analytic cost optimization was based on the following: (1) the VVT horizon covers five system lifecycle phases (Definition through Qualification) and (2) the VVT cost parameters are the same ones used during the pilot project. We also (1) have assumed that linear impact risk cost behavior and (2) have allowed each individual VVT APL (Xi,j) freedom to acquire any optimal value (i.e., in this section we assume a “free” mode for all decision variables).

Optimizing for Minimum Expected Total Cost

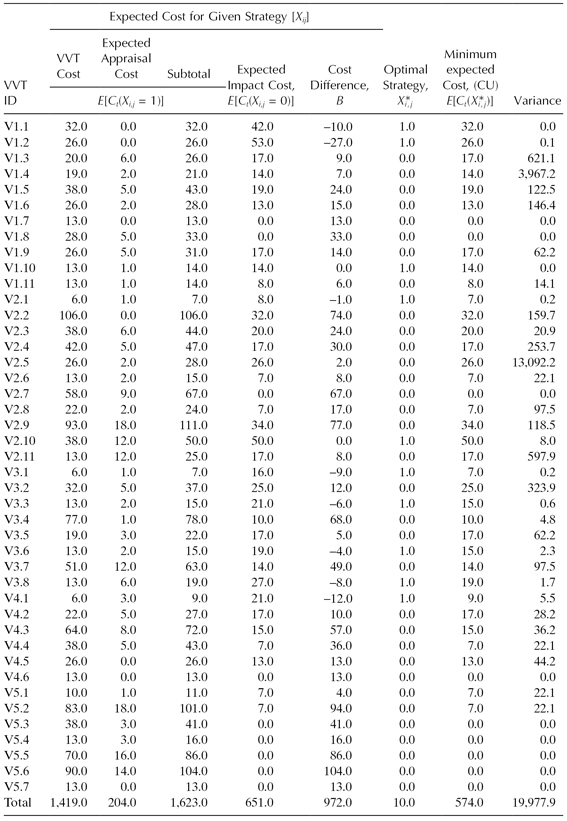

We shall now optimize the VVT strategy in order to obtain a minimum expected total cost. Table 8.10 presents the numerical results of the two pure strategies, Xi,j = 0, Xi,j = 1, which are the only potential optimal strategies.

TABLE 8.10 Optimizing for Minimum Expected Total Cost

As can be observed, the optimal strategy for obtaining minimum expected total cost is to fully perform 10 VVT activities and to not perform any of the other VVT activities. This optimal strategy yields a minimal ...

Get Verification, Validation, and Testing of Engineered Systems now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.