CHAPTER 5

Process Improvement: Reducing Waste Through Lean

CHAPTER IN PERSPECTIVE

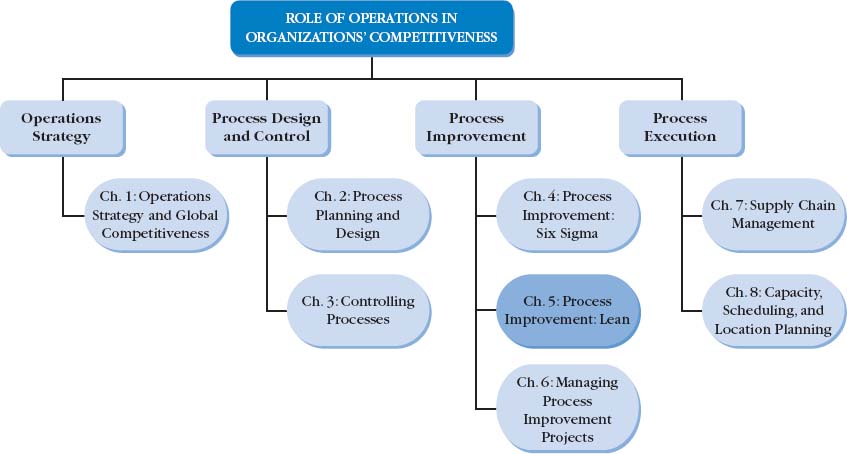

Based on their unique operations strategy, organizations design value-creating processes to achieve their strategy (Chapter 2). Frequently opportunities are identified to improve these processes either by completely redesigning the process through Business Process Design or reducing the variation inherent in the process through Six Sigma, as described in Chapter 4. In this chapter, we discuss another approach for process improvement that seeks to minimize waste and maximize value.

More specifically, “lean management” has taken on the aura of a global competitive philosophy because so many firms that embrace it have been so successful: Toyota, Deere, and numerous others. We first address the history and philosophy of lean and then make a comparison between traditional production systems and lean enterprises. Following this, we continue with a discussion of five lean principles: (1) specify value from the customer's point of view, (2) identify the value stream, (3) make value flow, (4) have the customer pull value, and (5) pursue perfection. The chapter concludes with a discussion of the benefits associated with lean.

INTRODUCTION

- It was not uncommon for chemotherapy patients at Virginia Mason Medical ...

Get Operations Management for MBAs, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.