CASE: Newmarket International Manufacturing Company (C)

Newmarket International Manufacturing Company (NIMCO) was founded by Marcia Blakely only two years after leaving graduate school. Her knowledge of mass customization was the driving force behind starting NIMCO. The company produces three major custom products. Volume on the products is high even though each item is customized specifically for the customer. The products are processed through up to four different work centers. Even though each item is unique, the processing time at each work center is constant due to the sophisticated equipment used.

Today's Opportunity

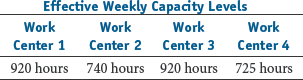

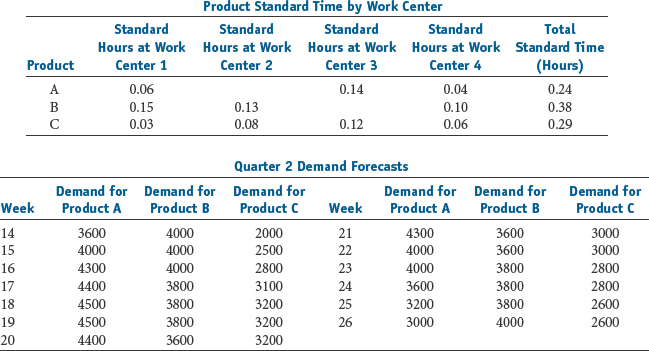

Joe Barnes had just left the staffing meeting. The information you provided was quite helpful, and he believes he has adequate resources to accomplish the required manufacturing for the second quarter. Effective capacity levels (including regular time and planned overtime) for each work center are shown here, as is the amount of time required for each product at each work center. The demand forecasts for each product are also shown.

1. Joe now needs a rough-cut capacity check to determine whether the capacity at each work center is adequate to support the expected demand. Using the forecasted demand as your proposed master schedule, calculate the load profile ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.