DEVELOPING AN MPS

The master scheduler develops a proposed MPS, checks the schedule for feasibility in terms of available capacity, modifies as needed, and authorizes the MPS. The master scheduler starts by creating, revising, and finishing an MPS record for each product. The master scheduler uses the finished MPS records to develop a proposed master production schedule, which he or she then checks for feasibility with a rough-cut capacity planning technique.

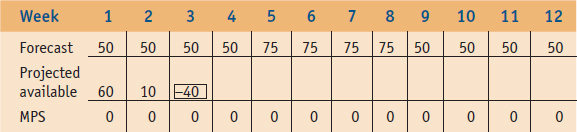

Consider the following examples of an MPS record for a product built in a make-to-stock environment with inventory held. The product is built in a fixed-order quantity of 125 units, and there are 110 units in beginning inventory. Table D-1 is an initial MPS record showing the demand forecasts for the next 12 weeks.

TABLE D-1 First MPS Record

The top row of the record shows the time periods (weeks, in our example); the forecast row shows the forecasted demand for the product. The projected available quantity row keeps track of how many units are available at the end of each time period. The MPS row shows when replenishment shipments need to arrive. MPS shipments arrive at the beginning of the time period. To calculate the projected available quantity, we use the following formula:

Projected available = beginning inventory + MPS shipment – forecasted demand

Period 1 To calculate the projected available quantity at the end of ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.