Solved Problems (See student companion site for Excel template.)

• Problem 1

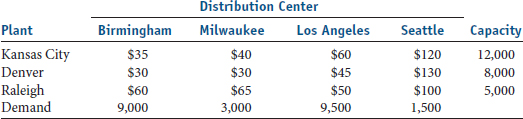

TowAlong makes trailers at plants in Kansas City, Denver, and Raleigh and ships these units to distribution centers in Birmingham, Milwaukee, Los Angeles, and Seattle. In planning production for the next year, TowAlong estimates unit shipping cost between any plant and distribution center, plant capacities, and distribution center demands. These numbers are given in the table. TowAlong faces the problem of determining how much to ship between each plant and distribution center to minimize the total transportation cost, while not exceeding capacity and while meeting demand.

- (a) Formulate an LP to minimize the total shipping cost.

- (b) Set up and solve the problem on a spreadsheet. What is the optimal solution?

• Before You Begin

In this problem, formulate an LP model to minimize the total shipping cost. After formulating the problem, put it into a spreadsheet model and use Solver to determine the optimal solution. First, formulate the objective function. This objective function has 12 decision variables. Each decision variable represents a specific route that could be used to satisfy demand. Each of the three plants can ship to each of the four distribution centers. Next, formulate the constraints. In this problem, there are plant capacity constraints and distribution center demand constraints. Next put ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.