CASE: The Navigator III

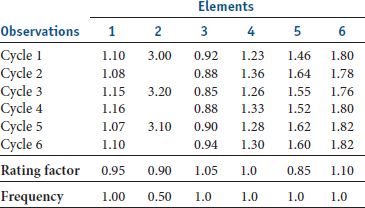

Frank Jones, the owner of Frank's Fabricators, has collected the following information to develop a standard time for producing the Navigator III, a universal remote control. All of the times are in minutes.

Frank has noticed that one of his senior operators, Sam, is able to consistently produce the Navigator III much quicker than other employees. However, Sam always produces exactly what the standard requires each day. Sam insists that he does everything according to the job directions. He offers no additional insight into how quickly he achieves the standard output levels.

During casual observations, Frank noticed that Sam appears to be doing element 6 much quicker than anyone else. Because of this, he asks Susan, a time-study analyst, to observe how Sam is doing element 6. After observing Sam, she determined that his mean observed time for element 6 was 1.50 minutes, and she rated his performance at 100 percent. This suggests that his output is not being accomplished by unusual effort on his part. Since Sam was significantly quicker than the standard but was only working at 100 percent, Susan suggested that he had developed a new method for doing element 6.

Questions

1. Based on Susan's observations, determine how long it actually takes Sam to produce a Navigator III.

2. If direct labor is assessed at $18 per hour, what would the labor savings per Navigator ...

Get Operations Management: An Integrated Approach, 5th Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.