Non-traditional Machining Processes

7.1 Electrical Discharge Machining (EDM)

Process Description

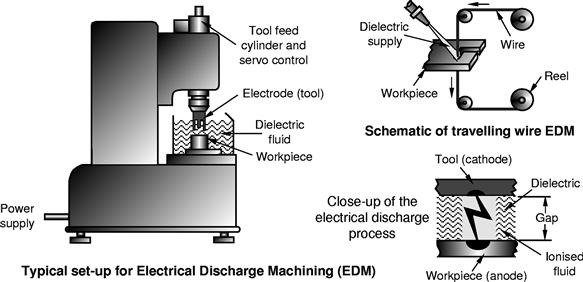

The tool, usually graphite, and the workpiece are essentially electrodes, the tool being the negative of the cavity to be produced. The workpiece is vaporised by spark discharges created by a power supply. The gap between the workpiece and tool is kept constant and a dielectric fluid is used to cool the vaporised ‘chips’ and then flush them away from the workpiece surface (Figure 7.1). Usually CNC control.

Figure 7.1 Electrical Discharge Machining (EDM).

Materials

• Any electrically conductive material irrespective of material hardness, ...

Get Manufacturing Process Selection Handbook now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.