Casting Processes

3.1 Sand Casting

Process Description

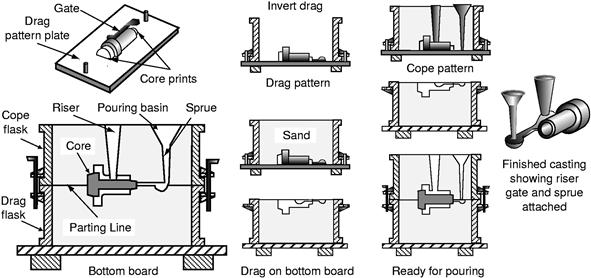

Moist bonding sand is packed around a pattern. The pattern is removed to create the mould and molten metal poured into the cavity. Risers supply necessary molten material during solidification. The mould is then broken to remove the part (Figure 3.1(a)).

Figure 3.1(a) Sand Casting.

Materials

Most metals, particularly ferrous and aluminium alloys. Some difficulty encountered in casting: lead, tin and zinc alloys, also refractory alloys, beryllium, titanium and zirconia alloys.

Process Variations

• Green sand casting: the most common and the cheapest. Associated problems are that ...

Get Manufacturing Process Selection Handbook now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.