28.1 Matrix Design Creation and Data Collection

Central composite designs are widely used because they allow us to plan the experimentation in two stages:

- A two level factorial design with centre points is carried out, checking for the need of quadratic terms.

- If a quadratic term is needed, ‘star’ points are added to allow the estimation of the pure quadratic terms.

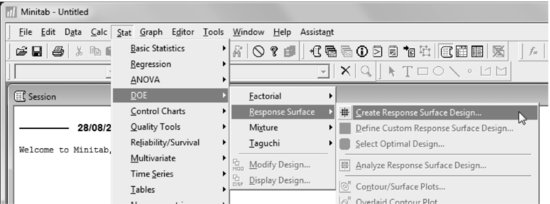

Stat > DOE > Response Surface > Create Response Surface Design

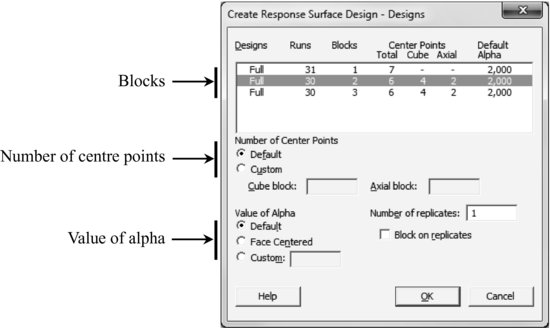

28.1.1 Designs

Blocks: Choose the number of blocks. Usually, each block corresponds to sequentially performed experiments. For example, if experiments are carried out in two different ...

Get Industrial Statistics with Minitab now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.