21.1 Bottles

The champagne bottles produced by a company dedicated to the manufacture of bottles and glass containers are the products of most impact in the turnover of that company. These bottles have specifications for: height, core diameter, external diameter of the mouth, inside diameter of the mouth, weight, horizontality, verticality, ovalization and thickness of the glass.

The presence of some quality problems highlights the need to launch a project for improvement. A preliminary study shows that 85% of the times that the bottle is out of the tolerance range, it is because of weight (too less weight is equivalent to lack of resistance) or ovalization. Thus, it is decided to focus actions for improvement on both of these aspects.

The process starts with mixing raw materials (silicon, sodium carbonate, and calcium; sometimes also glass for recycling) and continues with its merger, dripping, annealing, cold treatment, and palletizing. It is known, however, that the type of defects to attack can only occur during the dripping phase.

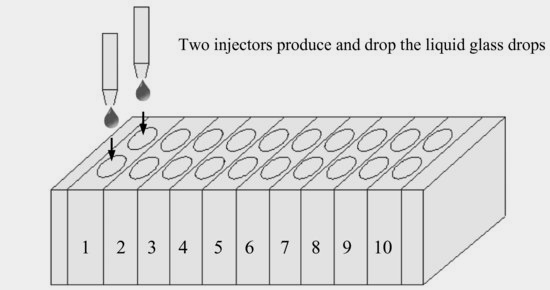

The dripping phase consists of introducing a drop of liquid glass (which will then be the bottle) into the cavity of the mould. The cavities are grouped in boxes of 20, which in turn consist of 10 sections with two cavities each. Each of these two cavities is fed by an injector, according to the scheme displayed on the previous page.

It is ...

Get Industrial Statistics with Minitab now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.