8.6 Equivalence between Sigmas of the Process and Defects per Million Parts Using ‘Cumulative Probability’

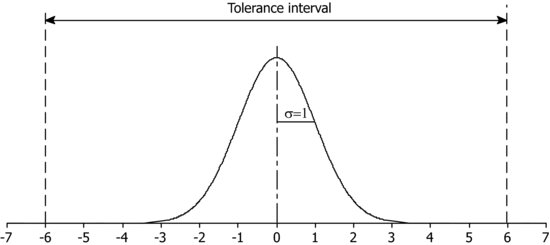

A process is said to be ‘Six Sigma’ when the distance between the nominal value and the tolerance limits of the produced output is equal to six times the standard deviation with which the output is produced. Likewise, a process is ‘Five Sigma’ if the tolerance limits are at five standard deviations, etc.

A Six Sigma process would look as follows:

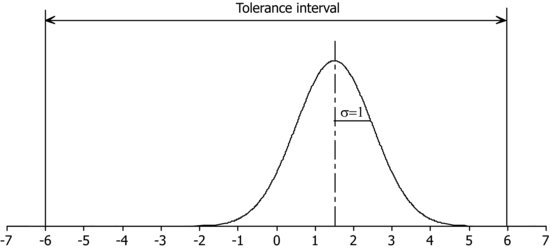

Knowing that the process will not always remain centred on its nominal value, it is assumed that the process is decentred 1.5 standard deviations to compute the proportion of defects that are produced. That is:

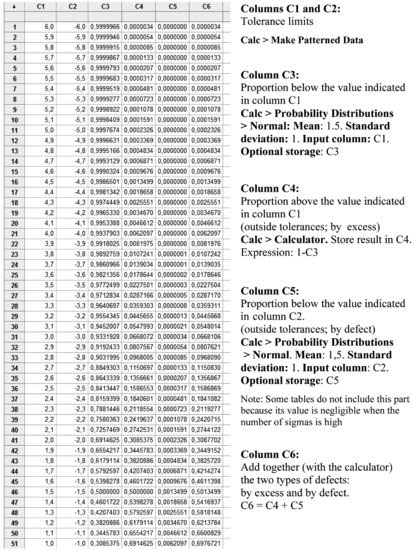

To compute the proportion of defects in relation to the sigmas of the process, set σ=1 and vary the tolerance values. Tolerances ±6 correspond to a 6σ process, ±5 to a 5σ process, etc.

The default number of decimal points has been changed in columns C3 to C6: Highlight the columns. Editor > Format Column > Numeric …

Column C6 contains the proportion of defects. To convert to ppm multiply these values by 1000000. For example, a process 3.5σ produces 22750 ppm.

Get Industrial Statistics with Minitab now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.