Chapter 15: Direct Quality Control

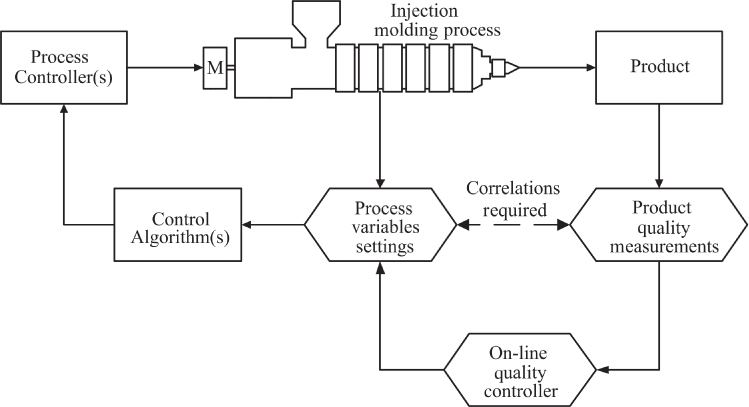

Part III of this book shows that different methodologies have been attempted to optimize the molded part quality, most of which used the process conditions as the set point parameters. However, even with a constant set point, the quality output could vary because of disturbances. Therefore, it is necessary to adopt the trajectories of the processing variables and/or quality variables as the inputs for process control. By now, relatively fewer attentions have been paid to the direct control of the final molded part qualities, probably due to the lack of an accurate quantitative description of the complex relation between the quality characteristics and the process conditions. At present, there do exist some imprecise qualitative relationships. Without the quantitative relations, an online control system of the injection molding product quality, as shown in Figure 15.1, is difficult to implement.

Figure 15.1 Block diagram of the desired online quality controller.

The complex thermal and rheological properties of the plastic material are the first difficulty in analyzing this relationship. The non-Newtonian flow ...

Get Computer Modeling for Injection Molding: Simulation, Optimization, and Control now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.