CHAPTER 11 Aircraft Engine Component Matching and Off-Design Analysis

11.1 Introduction

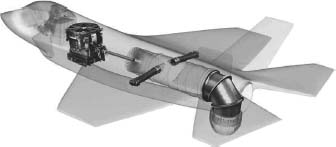

Source: Reproduced with permission from Rolls-Royce plc

How does an existing engine behave in an off-design operating condition? For an existing engine, we know its geometry and design-point parameters, such as compressor pressure ratio or turbine entry temperature. All the parameters that we used in the cycle analysis were in effect “design-point” parameters. For example, take compressor pressure ratio; it may be designed into a number of stages, each with a certain design pressure ratio. Although we cannot change the number of stages after the engine is manufactured, we may operate the compressor at a different shaft speed than its design speed, or, equivalently, we may operate the engine at a different throttle setting than its design. In general, the independent parameters that may be set and create an off-design flight condition for an airbreathing jet engine are

- Altitude of flight, which may include nonstandard ambient pressure and temperature, for example, arctic flight or seasonal effects

- Flight Mach number, from takeoff, climb, cruise, dash, approach, landing

- Throttle setting, that is, turbine entry temperature

- Afterburner setting, for example, -on, -off, or partial setting

- Nozzle area ratio setting, for example, to optimize installed thrust.

We will first consider individual ...

Get Aircraft Propulsion, 2nd Edition now with the O’Reilly learning platform.

O’Reilly members experience books, live events, courses curated by job role, and more from O’Reilly and nearly 200 top publishers.